뉴스 및 공지사항

- 관리자

- 2024.11.18

- 25

Humans’ ability to construct and use complex tools makes them different from animals. Many manufacturing applications such as sanding or composite layup require ergonomically challenging tool motions. Robots have successfully reduced the need for humans to perform tedious tasks in mass production applications. Robots are programmed by humans to execute pre-determined tool motions in mass production applications. However, high-mix applications require the part changeover to be accomplished within a few minutes, therefore, we cannot rely on humans to program robots when a new part arrives. Unfortunately, at present, the use of robots in high-mix manufacturing applications is limited, requiring humans to perform ergonomically challenging and physically demanding tasks. Using robots in these applications requires robots to autonomously manipulate tools based on high-level task descriptions and deliver human competitive task performance. This is a challenging problem and addressing it requires leveraging the latest advances in AI. This seminar will present an overview of embodied AI approaches that enable robots to learn safe and efficient autonomous tool manipulation. These new technologies serve as the foundation for realizing smart robotic cells for assembly, composite layup, additive manufacturing, and sanding applications. AI-based planning enables the automated generation of efficient robot trajectories for performing complex tool motions to meet process-specific requirements. Imitation learning enables robots to learn from human experts. The use of synthetic images generated from physics-informed simulations enables the use of deep learning in defect detection. Active learning enables the robotic cell to autonomously and safely conduct experiments to learn the process parameters in the most efficient manner. Smart robotic cells increase human productivity and reduce the need for humans to perform ergonomically challenging tasks.

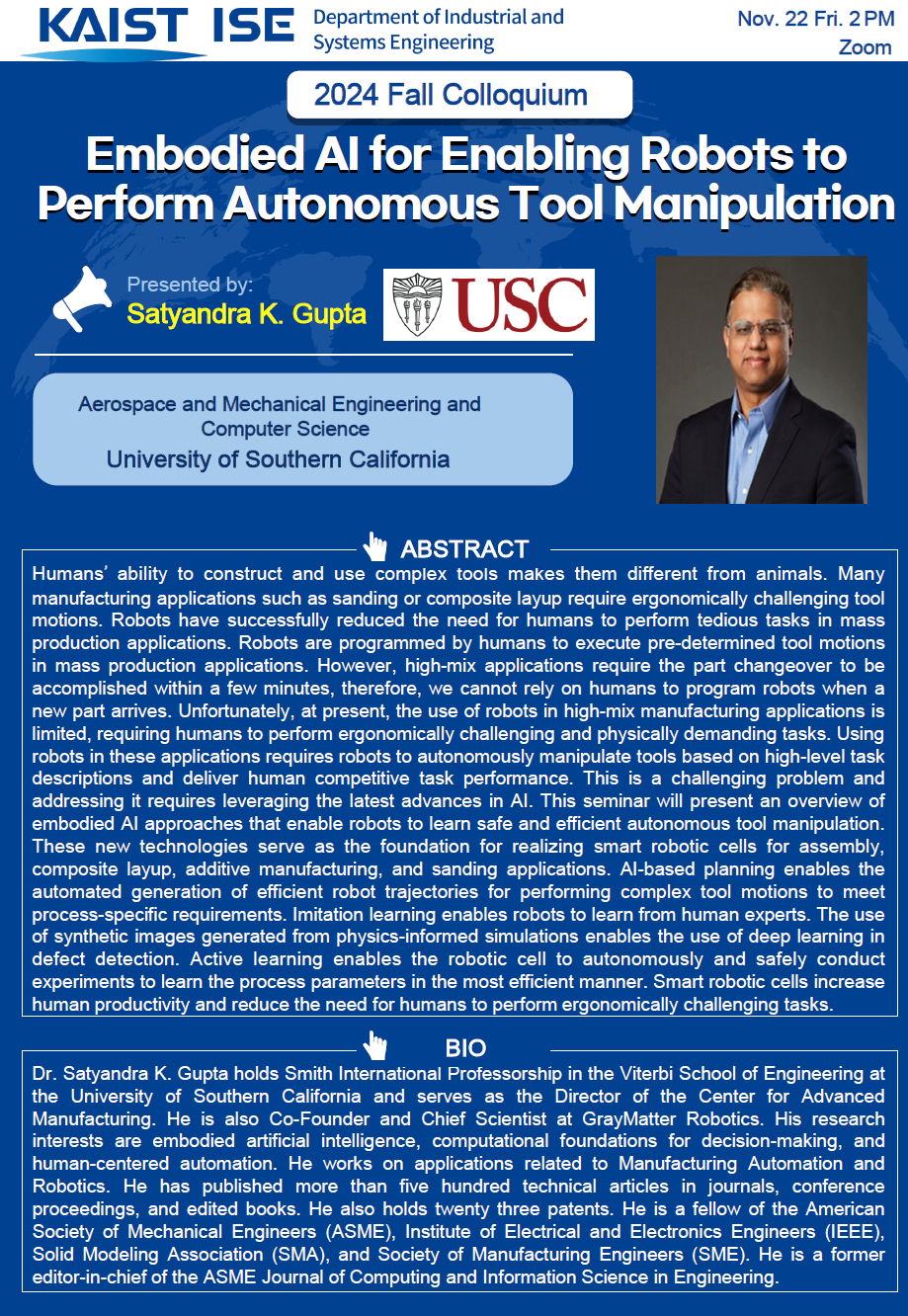

Dr. Satyandra K. Gupta holds Smith International Professorship in the Viterbi School of Engineering at the University of Southern California and serves as the Director of the Center for Advanced Manufacturing. He is also Co-Founder and Chief Scientist at GrayMatter Robotics. His research interests are embodied artificial intelligence, computational foundations for decision-making, and human-centered automation. He works on applications related to Manufacturing Automation and Robotics. He has published more than five hundred technical articles in journals, conference proceedings, and edited books. He also holds twenty three patents. He is a fellow of the American Society of Mechanical Engineers (ASME), Institute of Electrical and Electronics Engineers (IEEE), Solid Modeling Association (SMA), and Society of Manufacturing Engineers (SME). He is a former editor-in-chief of the ASME Journal of Computing and Information Science in Engineering. He has received numerous honors and awards for his scholarly contributions. Representative examples include a Young Investigator Award from the Office of Naval Research in 2000, Robert W. Galvin Outstanding Young Manufacturing Engineer Award from SME in 2001, a CAREER Award from the National Science Foundation in 2001, a Presidential Early Career Award for Scientists and Engineers in 2001, Invention of the Year Award at the University of Maryland in 2007, Kos Ishii-Toshiba Award from ASME in 2011, Excellence in Research Award from ASME Computers and Information in Engineering Division in 2013, Distinguished Alumnus Award from Indian Institute of Technology, Roorkee in 2014, ASME Design Automation Award in 2021, Distinguished Alumni Award from Indian Institute of Technology, Delhi in 2022, and Lifetime Achievement Award from ASME Computers and Information in Engineering Division in 2024. He has also received eleven best paper awards at international conferences. He serves as a member of the Technical Advisory Committee for Advanced Robotics for Manufacturing (ARM) Institute and a member of the National Materials and Manufacturing Board (NMMB).

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

# Location: Zoom https://kaist.zoom.us/j/82217529529

# Presenter: Prof. Satyandra K. Gupta / University of Southern California

Humans’ ability to construct and use complex tools makes them different from animals. Many manufacturing applications such as sanding or composite layup require ergonomically challenging tool motions. Robots have successfully reduced the need for humans to perform tedious tasks in mass production applications. Robots are programmed by humans to execute pre-determined tool motions in mass production applications. However, high-mix applications require the part changeover to be accomplished within a few minutes, therefore, we cannot rely on humans to program robots when a new part arrives. Unfortunately, at present, the use of robots in high-mix manufacturing applications is limited, requiring humans to perform ergonomically challenging and physically demanding tasks. Using robots in these applications requires robots to autonomously manipulate tools based on high-level task descriptions and deliver human competitive task performance. This is a challenging problem and addressing it requires leveraging the latest advances in AI. This seminar will present an overview of embodied AI approaches that enable robots to learn safe and efficient autonomous tool manipulation. These new technologies serve as the foundation for realizing smart robotic cells for assembly, composite layup, additive manufacturing, and sanding applications. AI-based planning enables the automated generation of efficient robot trajectories for performing complex tool motions to meet process-specific requirements. Imitation learning enables robots to learn from human experts. The use of synthetic images generated from physics-informed simulations enables the use of deep learning in defect detection. Active learning enables the robotic cell to autonomously and safely conduct experiments to learn the process parameters in the most efficient manner. Smart robotic cells increase human productivity and reduce the need for humans to perform ergonomically challenging tasks.

Dr. Satyandra K. Gupta holds Smith International Professorship in the Viterbi School of Engineering at the University of Southern California and serves as the Director of the Center for Advanced Manufacturing. He is also Co-Founder and Chief Scientist at GrayMatter Robotics. His research interests are embodied artificial intelligence, computational foundations for decision-making, and human-centered automation. He works on applications related to Manufacturing Automation and Robotics. He has published more than five hundred technical articles in journals, conference proceedings, and edited books. He also holds twenty three patents. He is a fellow of the American Society of Mechanical Engineers (ASME), Institute of Electrical and Electronics Engineers (IEEE), Solid Modeling Association (SMA), and Society of Manufacturing Engineers (SME). He is a former editor-in-chief of the ASME Journal of Computing and Information Science in Engineering. He has received numerous honors and awards for his scholarly contributions. Representative examples include a Young Investigator Award from the Office of Naval Research in 2000, Robert W. Galvin Outstanding Young Manufacturing Engineer Award from SME in 2001, a CAREER Award from the National Science Foundation in 2001, a Presidential Early Career Award for Scientists and Engineers in 2001, Invention of the Year Award at the University of Maryland in 2007, Kos Ishii-Toshiba Award from ASME in 2011, Excellence in Research Award from ASME Computers and Information in Engineering Division in 2013, Distinguished Alumnus Award from Indian Institute of Technology, Roorkee in 2014, ASME Design Automation Award in 2021, Distinguished Alumni Award from Indian Institute of Technology, Delhi in 2022, and Lifetime Achievement Award from ASME Computers and Information in Engineering Division in 2024. He has also received eleven best paper awards at international conferences. He serves as a member of the Technical Advisory Committee for Advanced Robotics for Manufacturing (ARM) Institute and a member of the National Materials and Manufacturing Board (NMMB).